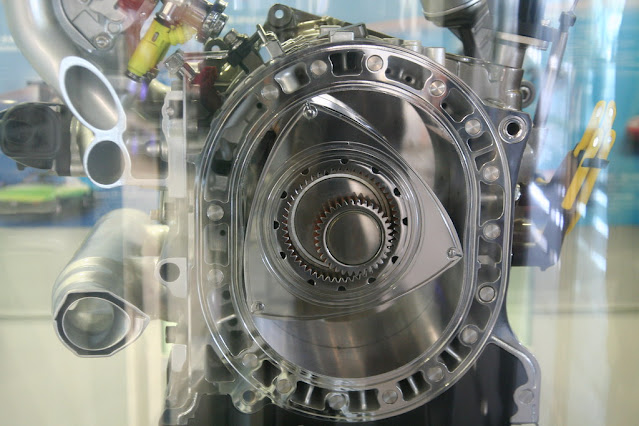

The Wankel (rotary) engine has a unique performance profile compared to traditional piston engines. Below is a detailed breakdown of its key performance characteristics:

%20Engine.jpg)

1. Power Output & RPM Capability

✅ High Power-to-Weight Ratio

Fewer moving parts = lighter engine.

Example: Mazda 13B (1.3L twin-rotor) produces 232 HP naturally aspirated (~178 HP/L), while turbocharged versions (e.g., RX-7 FD3S) reached 276+ HP.

Racing variants (e.g., Le Mans 787B) exceeded 700 HP in 4-rotor configurations.

✅ Extremely High Revving

No reciprocating mass (unlike pistons) allows 10,000+ RPM in race-tuned engines.

Smoother power delivery due to continuous rotation.

❌ Low Torque at Low RPM

Weak low-end torque due to poor combustion efficiency at low speeds.

Requires high RPMs (5,000+) for peak power (similar to motorcycle engines).

2. Fuel Efficiency & Emissions

❌ Poor Fuel Economy

Long, thin combustion chamber leads to slow flame propagation and incomplete burning.

Typically 20-30% worse fuel efficiency than equivalent piston engines.

❌ High Emissions (Especially Hydrocarbons)

Unburnt fuel escapes due to poor combustion sealing.

Early Wankels struggled to meet emissions standards (leading to the RX-8’s discontinuation).

3. Reliability & Durability

✅ Fewer Moving Parts = Less Wear

No valves, camshafts, or connecting rods = lower mechanical stress.

❌ Apex Seal Failures (Biggest Weakness)

Apex seals (critical for compression) wear out quickly under high boost or poor lubrication.

Turbocharged Wankels (e.g., RX-7) often require rebuilds every 80,000–100,000 miles.

Oil injection system (to lubricate seals) increases oil consumption.

check this out : Wankel Engine (Rotary Engine) - Overview

4. Thermal Efficiency & Heat Management

❌ Low Thermal Efficiency (~20-25%)

Poor combustion chamber shape = wasted energy.

Piston engines (especially diesels) achieve 30-40%+ efficiency.

❌ Overheating Issues

Hot spots develop in the housing due to uneven heat distribution.

Cooling system must be robust (RX-7 had two oil coolers).

5. Performance Comparison: Wankel vs. Piston Engine

| Metric | Wankel Engine | Piston Engine |

|---|---|---|

| Power Density | ⭐⭐⭐⭐⭐ (Very High) | ⭐⭐⭐ (Moderate) |

| Torque (Low RPM) | ⭐ (Weak) | ⭐⭐⭐⭐ (Strong) |

| Max RPM | ⭐⭐⭐⭐⭐ (10,000+) | ⭐⭐⭐ (6,000-8,000) |

| Fuel Efficiency | ⭐ (Poor) | ⭐⭐⭐⭐ (Better) |

| Emissions | ⭐ (High HC/CO) | ⭐⭐⭐ (Cleaner) |

| Reliability | ⭐⭐ (Seal Wear) | ⭐⭐⭐⭐ (More Durable) |

check this out : Electronic Catalytic Converter: Next-Gen Emission Control

6. Racing & High-Performance Applications

Despite drawbacks, Wankels excelled in motorsports:

Mazda 787B (Le Mans 1991 Winner) – 4-rotor, 900 HP, first (and only) rotary-powered car to win Le Mans.

RX-7 (Group B, IMSA GTP) – Dominated with turbocharged 13B engines.

Drag Racing – Lightweight + high RPM = great for power-to-weight builds.

7. Modern Developments & Future Potential

🔧 Mazda’s Rotary Revival (MX-30 e-Skyactiv R-EV)

Uses a Wankel as a range extender (not primary drive), improving efficiency.

🔥 Hydrogen Wankel Research

Hydrogen burns cleaner and could solve emissions issues.

Mazda tested hydrogen-powered RX-8 prototypes.

🚁 Drone & UAV Applications

Lightweight + high-RPM advantage makes it ideal for aviation.

check this out : 20 questions answered about Ignition System type

Conclusion: Who Should Use a Wankel Engine?

✔ Best For:

Racing (high-RPM power, lightweight).

Enthusiasts (unique sound, smooth power).

Hybrid/range-extender applications (Mazda’s new approach).

❌ Worst For:

Daily drivers (fuel costs, reliability concerns).

Off-road/towing (low torque).

The Wankel remains a niche but fascinating engine, beloved for its high-revving character and compact design, but held back by efficiency and durability issues.

Post a Comment