Variable Compression Ratio (VCR) is an advanced engine technology that dynamically adjusts the compression ratio to optimize efficiency, power, and emissions under different operating conditions. This innovation helps balance performance and fuel economy better than fixed-compression engines.

1. What is Compression Ratio (CR)?

Definition: The ratio of the cylinder's maximum volume (when piston is at BDC) to minimum volume (when piston is at TDC).

Typical Values:

Gasoline engines: 8:1 to 12:1 (higher in turbocharged engines).

Diesel engines: 15:1 to 22:1 (due to compression ignition).

Why Adjust Compression Ratio?

High CR at low load → Better thermal efficiency (fuel economy).

Low CR at high load → Prevents knocking (allows higher boost in turbo engines).

2. How VCR Works: Key Technologies

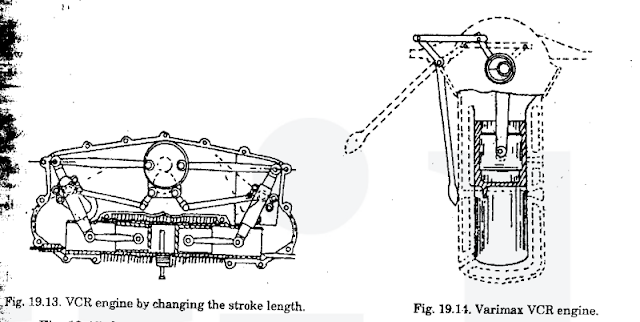

Several engineering approaches exist to vary compression ratio dynamically:

(A) Piston Height Adjustment (Nissan VC-Turbo)

Mechanism: A multi-link system alters piston stroke length.

How it works:

An actuator adjusts the multi-link pivot point, changing the piston’s top dead center (TDC).

CR Range: 8:1 (high power) to 14:1 (high efficiency).

Used in: Nissan 2.0L VC-Turbo (e.g., Infiniti QX50).

(B) Moving Cylinder Head (SAAB SVC)

Mechanism: The cylinder head tilts to change combustion chamber volume.

How it works:

A hydraulic system pivots the head, altering the compression space.

CR Range: 10:1 to 14:1.

Status: Never mass-produced (SAAB prototype).

(C) Variable Conrod Geometry (Peugeot & MCE-5)

Mechanism: A hydraulic actuator changes connecting rod length.

How it works:

Adjusts piston position relative to the crankshaft.

CR Range: 7:1 to 20:1 (theoretical).

Status: Experimental (not commercialized).

check this out : Reciprocating Compressor: Working Principle, Types & Applications

3. Benefits of VCR Engines

✅ Improved Fuel Efficiency (up to 10-15% better than fixed-CR engines).

✅ Knock Prevention (allows higher boost in turbo engines without pre-ignition).

✅ Lower Emissions (optimized combustion reduces NOx and CO₂).

✅ Flexible Performance (high CR for economy, low CR for power).

check this out : Wankel Engine (Rotary Engine) - Overview

4. Challenges & Drawbacks

❌ Complexity & Cost (additional moving parts increase manufacturing cost).

❌ Reliability Concerns (wear and tear on adjustment mechanisms).

❌ Limited Adoption (only Nissan has mass-produced a VCR engine).

5. Current & Future Applications

Nissan VC-Turbo (2.0L) – First production VCR engine (2018).

Hyundai & Kia Research – Testing VCR for hybrid applications.

Formula 1 (Future Potential) – Could help optimize turbo-hybrid powertrains.

Conclusion: Is VCR the Future?

Best for: Turbocharged engines, hybrids, and high-efficiency applications.

Biggest hurdle: Cost vs. benefit compared to simpler solutions (e.g., variable valve timing, mild hybridization).

Outlook: Likely to grow in premium/hybrid vehicles but may not replace fixed-CR engines entirely.

Post a Comment