Scavenging refers to the process of removing exhaust gases from the combustion chamber and replacing them with a fresh air-fuel mixture. There are several types and classifications of scavenging processes:

Theoretical Scavenging Processes

Perfect Scavenging:

- In this ideal scenario, all exhaust gases are completely expelled from the cylinder, and the entire charge is replaced with a fresh air-fuel mixture. There is no mixing of the old and new gases, resulting in maximum efficiency.

Perfect Mixing:

- Here, the exhaust gases and fresh mixture intermingle within the cylinder. This process assumes optimal conditions where there is uniform mixing, but it may result in some loss of fresh charge due to incomplete flushing of exhaust gases.

Short Circuit:

- In short circuiting, the fresh charge bypasses the combustion chamber and escapes through the exhaust ports before effectively scavenging the exhaust. This leads to significant efficiency losses as some of the air-fuel mixture is wasted.

check this : scavenging pumps and blowers

Types of Scavenging Methods

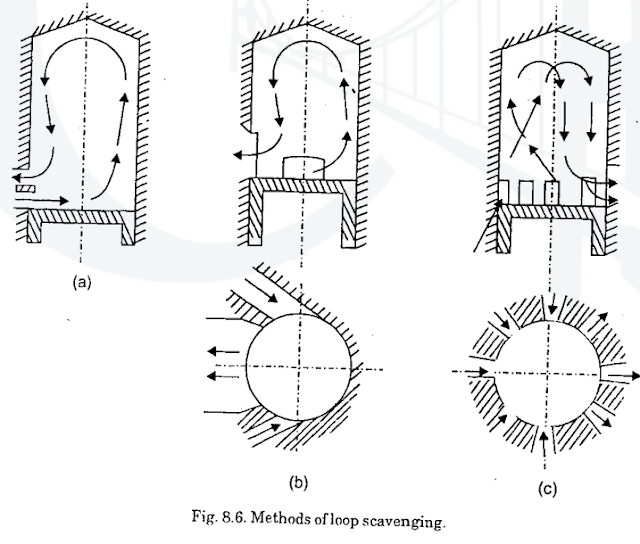

Loop (or Reverse) Scavenging:

- In this design, the fresh charge enters from one side of the cylinder and flows up and over the exhaust outlet before exiting. This motion creates a loop, promoting effective scavenging but can lead to mixing if not managed properly.

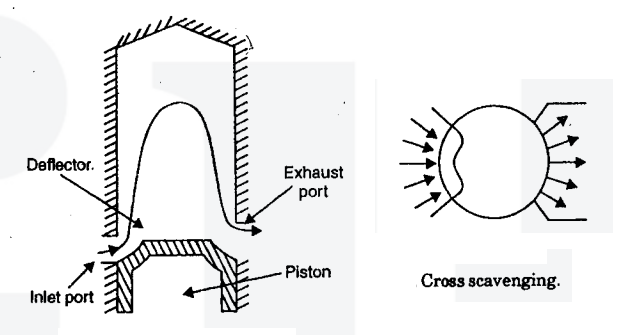

Cross Scavenging:

- Fresh charge enters the cylinder from one side and exhaust exits from the opposite side. This method creates a crossflow pattern. While effective in some designs, it can generate turbulence, and a portion of the fresh charge might remain in the exhaust.

Uniflow Scavenging:

- The charge enters from one end of the cylinder and exhaust exits from the other end, creating a linear flow. This method is known for its efficacy in maintaining scavenging efficiency with minimal backflow of exhaust gases, which is beneficial for performance.

- check this : battery ignition system: Components, types, and how it works

Crankcase Scavenging

Overview:

This method utilizes the crankcase as part of the scavenging process. The air-fuel mixture is drawn into the crankcase during the downward stroke of the piston, which creates a vacuum. As the piston rises, the pressure difference facilitates the transfer of this mixture into the combustion chamber.Characteristics:

- The crankcase acts as a reservoir for the fresh charge, allowing for better mixing and control over the air-fuel ratio.

- It simplifies the engine design by eliminating the need for complex intake systems.

- The process can improve power output and efficiency, especially in smaller two-stroke engines.

Advantages:

- Increases engine responsiveness and power output.

- Reduces the need for external components to manage intake and exhaust.

Disadvantages:

- Can lead to increased oil consumption and emissions due to oil being mixed with the fuel for lubrication within the crankcase.

check this : Scavenging Process in 2-stroke engine explained

Summary

Understanding the different scavenging processes and methods is essential for optimizing 2-stroke engine performance. Each process has its advantages and disadvantages, and the choice of scavenging type can significantly impact engine efficiency, power output, and emissions.

If you have any further questions or need detailed information on a specific type, feel free to ask!

Post a Comment