Naturally Aspirated (NA) Cycle of Operation

Process:

Intake Stroke: Air-fuel mixture enters at atmospheric pressure (~1 bar).

Compression Stroke: Mixture is compressed (CR: 8:1 to 12:1).

Power Stroke: Spark plug ignites mixture, expanding gases.

Exhaust Stroke: Burnt gases exit at near-atmospheric pressure.

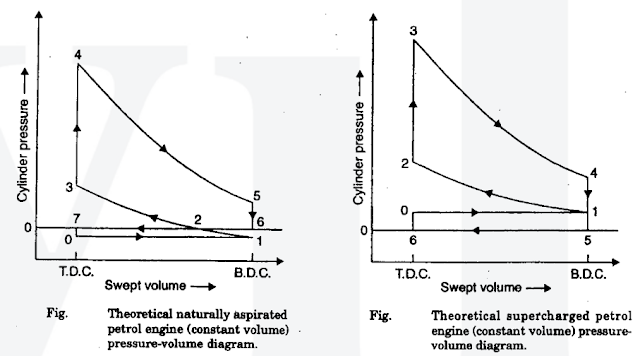

PV Diagram:

Shows a narrow loop with lower peak pressure (limited by ambient air density).

Work output per cycle = Area enclosed by the cycle.

2. Actual NA vs. Supercharged Engine Comparison

| Parameter | Naturally Aspirated | Supercharged |

|---|---|---|

| Intake Pressure | ~1 bar (atm) | 1.5–2.5 bar (boosted) |

| Air Density | Lower | Higher (more O₂ molecules) |

| Volumetric Efficiency | 70–90% | 100–150% (forced induction) |

| Power Output | Limited by displacement | +30–50% (or more) |

| Thermal Efficiency | Higher (no parasitic loss) | Slightly lower (energy to drive SC) |

Thermodynamic Cycle & Supercharging Power Otto Cycle Modifications:

Increased 𝑃₃ (peak pressure): More air/fuel → Higher expansion work.

Higher 𝑇₃ (combustion temp): Requires premium fuel (higher octane).

Power Gain Equation:

Example: 1.5 bar boost → ~50% more power.

Parasitic Loss: Supercharger consumes 5–15% of engine power.

Key Points on Supercharging S.I. Engines

Knocking Risk:

Higher pressure/temperature can cause pre-ignition (requires high-octane fuel).

Heat Management:

Intercoolers must reduce intake air temp (↓ detonation risk).

Fuel Enrichment:

Extra fuel is often injected to cool combustion chambers.

Compression Ratio (CR):

Supercharged engines typically run lower CR (e.g., 8:1 vs. 11:1 NA).

Emissions:

Higher NOx due to increased combustion temps (may need EGR).

Supercharging Limits in S.I. Engines

Knocking Threshold:

Practical boost limit: ~1.5–2.0 bar (varies with fuel octane and cooling).

Material Strength:

Pistons/rods must handle higher peak pressures.

Thermal Stress:

Exhaust valves and turbo components face extreme heat.

Fuel Quality:

Low-octane fuel severely limits boost potential.

Summary Table: Supercharging vs. NA S.I. Engines

| Aspect | Naturally Aspirated | Supercharged |

|---|---|---|

| Peak Power | Limited by displacement | +30–50% typical |

| Throttle Response | Good | Instant (vs. turbo lag) |

| Efficiency | Higher (no parasitic loss) | Lower (SC consumes power) |

| Knocking Risk | Low | High (requires mitigation) |

| Cost | Lower | Higher (hardware + tuning) |

Final Notes

Supercharging trades efficiency for power density.

Best for applications where low-end torque and throttle response are critical (e.g., drag racing, muscle cars).

Modern solutions combine supercharging + turbocharging (e.g., Volvo’s Twin-Charged engines).

Post a Comment