Here’s a detailed breakdown of engine cooling systems, including diagrams, types, and how they work:

1. Engine Cooling System Diagram

(Key components and flow path)

A typical liquid-cooled system consists of:

[Engine Block] → [Water Pump] → [Radiator] → [Thermostat] → [Coolant Reservoir]

↑____________[Cooling Fan] ←________↓

Visual Flow:

- Coolant absorbs heat from the engine block/cylinder head.

- Water pump circulates hot coolant to the radiator.

- Radiator dissipates heat via airflow (natural or fan-assisted).

- Thermostat regulates coolant flow (opens at ~90°C).

- Coolant reservoir compensates for expansion/contraction .

(For a detailed diagram, refer to manufacturer guides like Haynes or Shutterstock’s infographic .)

check this out : Reciprocating Compressor: Working Principle, Types & Applications

2. Types of Engine Cooling Systems

A. Air Cooling System

- Components: Finned cylinders, fan, ducting.

- How it works: Air flows over fins to dissipate heat (common in older VW Beetles, motorcycles) .

- Pros: Simpler, lighter, no coolant leaks .

- Cons: Uneven cooling, noisy, less efficient for high-power engines .

B. Liquid Cooling System

- Components: Radiator, water pump, thermostat, hoses, coolant.

Subtypes:

- Thermosiphon: Natural convection (no pump; outdated) .

- Forced Circulation: Uses a water pump (standard in modern cars).

- Pros: Precise temperature control, better for high-performance engines .

- Cons: Complex, requires maintenance (e.g., coolant flushes) .

3. How cooling system works

Step-by-Step Process :

Cold Start:

Thermostat closed; coolant circulates only in the engine block for quick warm-up.

Normal Operation:

At ~90°C, thermostat opens, allowing coolant to flow to the radiator.

Radiator cools coolant via airflow (natural or fan-assisted).

Heat Dissipation:

Pressure Regulation:

Overflow Management:

check that out :Wankel (rotary) Engine Performance: Strengths & Limitations

4. Key Components of cooling systems

Component Function

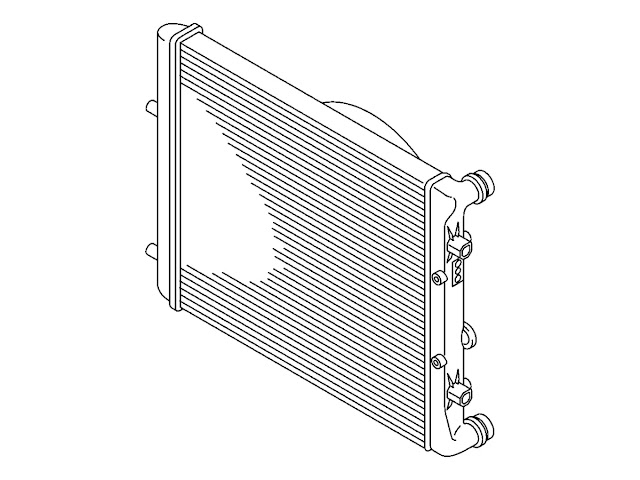

Radiator Cools hot coolant via air exchange (aluminum/plastic construction).

Water Pump Circulates coolant (belt-driven or electric).

Thermostat Regulates coolant flow (opens at 75–90°C).

Cooling Fan Electric/viscous fan aids airflow at low speeds.

Coolant 50% water + 50% antifreeze (prevents freezing/boiling, inhibits corrosion).

Hoses Routes coolant between components (rubber/silicone).

Heater Core Diverts warm coolant to heat the cabin.

5. Common Issues & Maintenance

- Overheating: Caused by low coolant, faulty thermostat, or clogged radiator.

- Leaks: Check hoses, water pump seals, and radiator for cracks.

Post a Comment